But, on resuming my further researches, after my return to London, an incident occurred which suddenly put a stop to the intended works at the Ruelle gun-foundry, and in fact altered all my future plans and investigations.

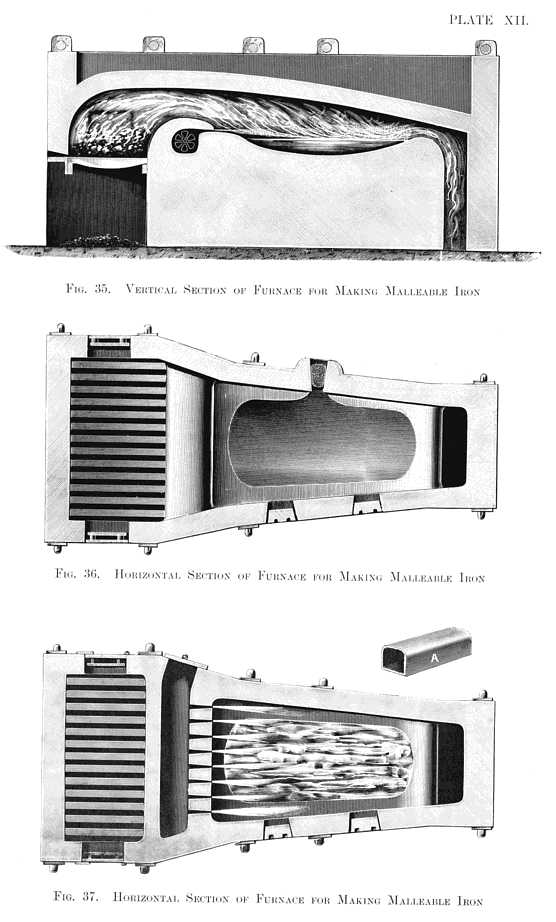

The furnace, as then arranged, is shown in vertical section in Fig. 35, and in horizontal section, on the line passing above the fire-bridge, in Fig.36, Plate XII., the bath being empty and showing the tapping- hole, and the way in which the furnace narrows at the fire-bridge. Fig. 37, on the same Plate, is also a horizontal section, taken on a line passing through the openings in the perforated hollow fire-bridge, and clearly shows how the jets of air were directed so as to produce an intense ignition of the combustible gases, mingled with, and passing over with, the large volume of flame from the overcharged fire-grate.

The small scale on which this experimental furnace was built (a capacity of 3 cwt. only) was much against my obtaining the high temperature necessary to melt a large proportion of steel in a pig-iron bath. I was, of course, fully aware that a furnace of sufficient capacity to cast a 5-ton or a 10-ton gun would acquire a much higher temperature than was possible in my small furnace. I knew also that forced draught, obtained by closing in the ashpit and forcing air into it, would still further increase the temperature. That this forced draught was in my mind at the time is shown by the fact that I took out a patent for the manufacture of cast steel, dated October 17th, 1855; that is, about two months after the casting of the model gun, in which specification I fully described the forcing of air by a fan into the closed ashpits of the furnaces employed in the manufacture of cast steel. It has since often occurred to me that, with these additional resources still untried, I did not act wisely in so suddenly abandoning these open-hearth experiments, in favour of an entirely different system, suggested to my mind by the incident to be presently referred to. But with my impulsive nature, and intense desire to follow up every new problem that presented itself, I at once threw myself unreservedly into this new study, which seemed to open the way to the rapid production of bars, rails, and plates of malleable metal direct from the blast-furnace.

Before dismissing this subject, it may be interesting, even at this distant period, to speculate on what would have been the natural outcome of my open-hearth furnace experiments, had I not been so suddenly diverted from their further pursuit.

Such a furnace, with forced draught and a capacity of 10 tons, would undoubtedly have melted malleable iron or steel in a bath of pig iron, and have decarburised the latter to the desired extent; for I had, in fact, already fused steel, in a bath of pig iron, on the open hearth of this small reverberatory furnace; and as far back as January, 1855, I had claimed in my patent, "The fusion of steel in a bath of melted pig or cast iron in a reverberatory furnace, as herein described."

This was about ten years prior to the patent taken out by M. Emile Martin, and now generally known as the "Siemens-Martin process." This latter patent was obtained in England in the name of A. Brooman, the patent agent of Emile Martin, and is dated August 18th, 1865, or more than ten years after my patent of January 10th, 1855. M. Emile Martin in his patent says: "The manufacture is effected upon the principle of fusion of iron or natural steel in a bath of cast iron, maintained at a white heat in a reverberatory furnace, such as Siemens gas furnace."

I, however, desire to say that I make no claim to the prior invention of the Siemens-Martin process, nor do I assume that my patent of 1855 furnished any information which either of these gentlemen had availed themselves of, although my patent for melting steel in a bath of cast iron on the hearth of a reverberatory furnace had been granted, and the specification published, some nine years prior to M. Martin's application for his patent. But seeing how many years I was in advance of M. Martin, I feel perfectly justified in saying that the fusion of steel in a bath of pig iron on the open hearth of a reverberatory furnace, which I had patented and accomplished ten years prior to the Siemens-Martin patent, was, to use a favourite expression of Mr. Gladstone, "approaching within measurable distance" of that successful process known as the open-hearth manufacture of mild steel.

| Previous chapter/page | Back | Home | Email this | Search | Discuss | Bookmark | Next chapter/page |