Lowmoor iron bars, from which the Armstrong gun coils were made. I cannot tell the precise date of the actual production of the cup illustrated, but I know it was many months before the great Exhibition of 1862. I can trace it back to that period by evidence that cannot be disputed. The Engineer newspaper of the first week in May, 1862, describing my exhibit of Bessemer steel, says:

There are also some extraordinary examples of the toughness of Bessemer steel made from British coke-made pig-iron, among which may be enumerated two deep vessels of one foot in diameter, with flattened bottoms and vertical sides; at the top edge, one of them is 5/8 in. and the other 7/8 in. in thickness. These are formed up in a press from flat circular discs of steel.

They can now be drawn into long tubes, either of their present diameter, or they may be reduced to locomotive boiler tubes of 2 in. in diameter; there is also shown an attempt to raise a piece of the best Staffordshire iron plate by the same tools; this only went about as deep in proportion as an ordinary soup plate before it fractured all around the punch, and almost fell into two pieces. It may be remembered that Mr. Parkes, who invented this beautiful system of making unwelded tubes, has been obliged to use the very highest quality of copper for that purpose; the ordinary copper of commerce generally cracks, but the Bessemer steel, as seen by these examples, stands this fearful ordeal with perfect safety.

On the closing of the Exhibition of 1862, I presented this cup to Dr. Percy, who placed it in the gallery of the Geological Museum in Jermyn Street, whence it was, many years ago, transferred to the South Kensington Museum. The Curator kindly allowed me to have a photograph taken of it, and from this photograph the engraving on Plate XX. has been made.

Since writing the above, I have called to memory an earlier date on which one of these deep cups was exhibited. I refer to the occasion of Sir William Armstrong's visit to Sheffield, as President of the Institution of Mechanical Engineers, which held its summer meeting there on July 31st, 1861; in proof of this I refer to the copy of my Paper as printed and issued by that Institution. In the Proceedings of the Institution the Secretary interpolated, between the reprint of my Paper and the report of the discussion thereon, the announcement which is here reproduced.

Mr. Bessemer exhibited an 18-pounder gun made of the Bessemer steel cast in a single ingot of the required size and subsequently hammered, with a variety of specimens of the metal, broken to show the quality of the fracture; also some piston rods, a boiler plate flanged for a locomotive fire-box, and a plate bulged in a die without cracking or tearing; a plate of thin metal punched with a number of small holes very close together, and a tube of the metal which had been crushed flat without the surface of the metal cracking. He showed also one of the fireclay tuyères used for blowing the melted metal in the converting vessel, and specimens of the ganister used for lining the vessel and ladle, both new and after use.

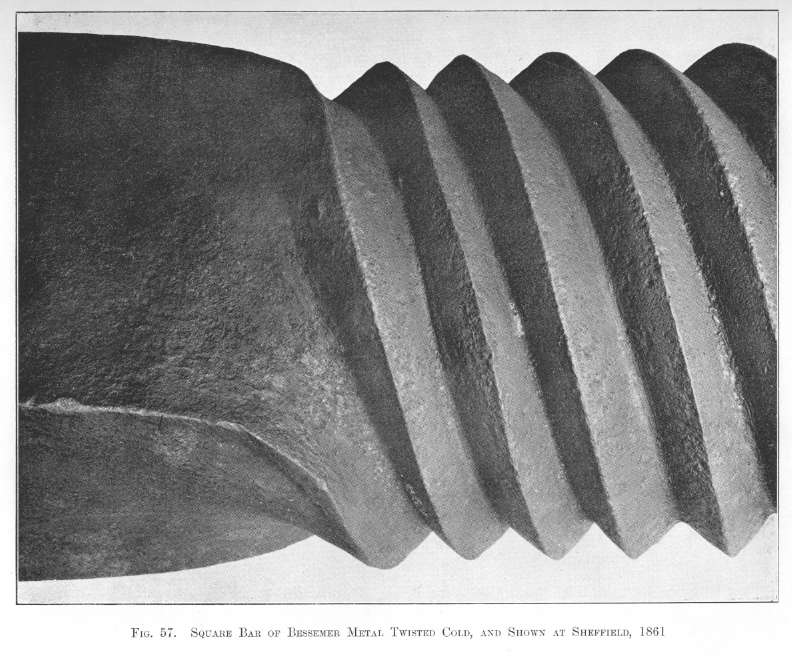

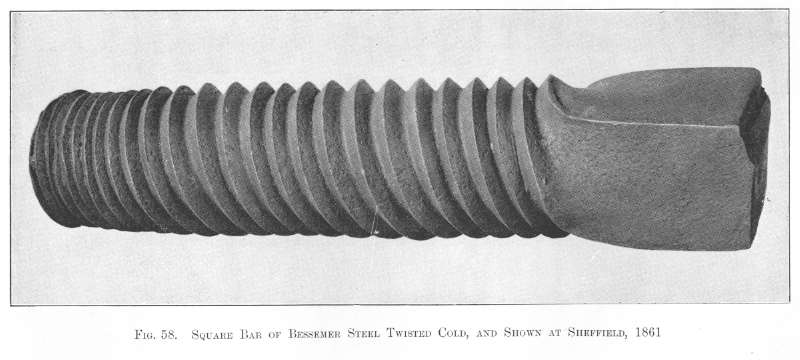

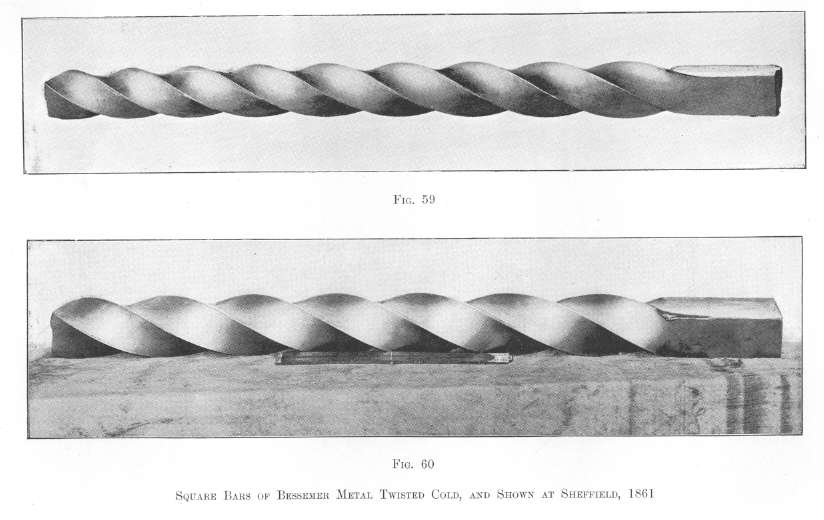

The "variety of specimens of the metal broken to show the quality of the fracture" should have been described as "specimens crushed to show the toughness of the steel." "A plate bulged in a die" is the deep cup made from a flat piece of boiler plate 27 in. diameter, and already mentioned as being illustrated in Fig. 56, Plate XX. The tube of metal crushed flat without cracking (see C, Fig. 49, Plate XIX.) was similar to the crushed gun-tubes so many years exhibited in the South Kensington Museum, and now in the possession of the Iron and Steel Institute. Figs. 57 to 60, on Plates XXI, XXII., and XXIII., show other specimens exhibited at the meeting.

It is unnecessary to multiply examples, since those already given cannot fail to convince any unprejudiced person that in these early days of the Bessemer process all those manufacturers who understood it, and took the amount of care which is necessary in all properly-conducted manufacturing operations, were able to produce steel of high quality with as great a degree of regularity as is common with any other modes of production. I, however, cannot refrain from giving yet another instance of the wonderful tenacity and endurance of this metal when subjected to the most violent strains.

| Previous chapter/page | Back | Home | Email this | Search | Discuss | Bookmark | Next chapter/page |